Natural and Safe Dehydrating Solution

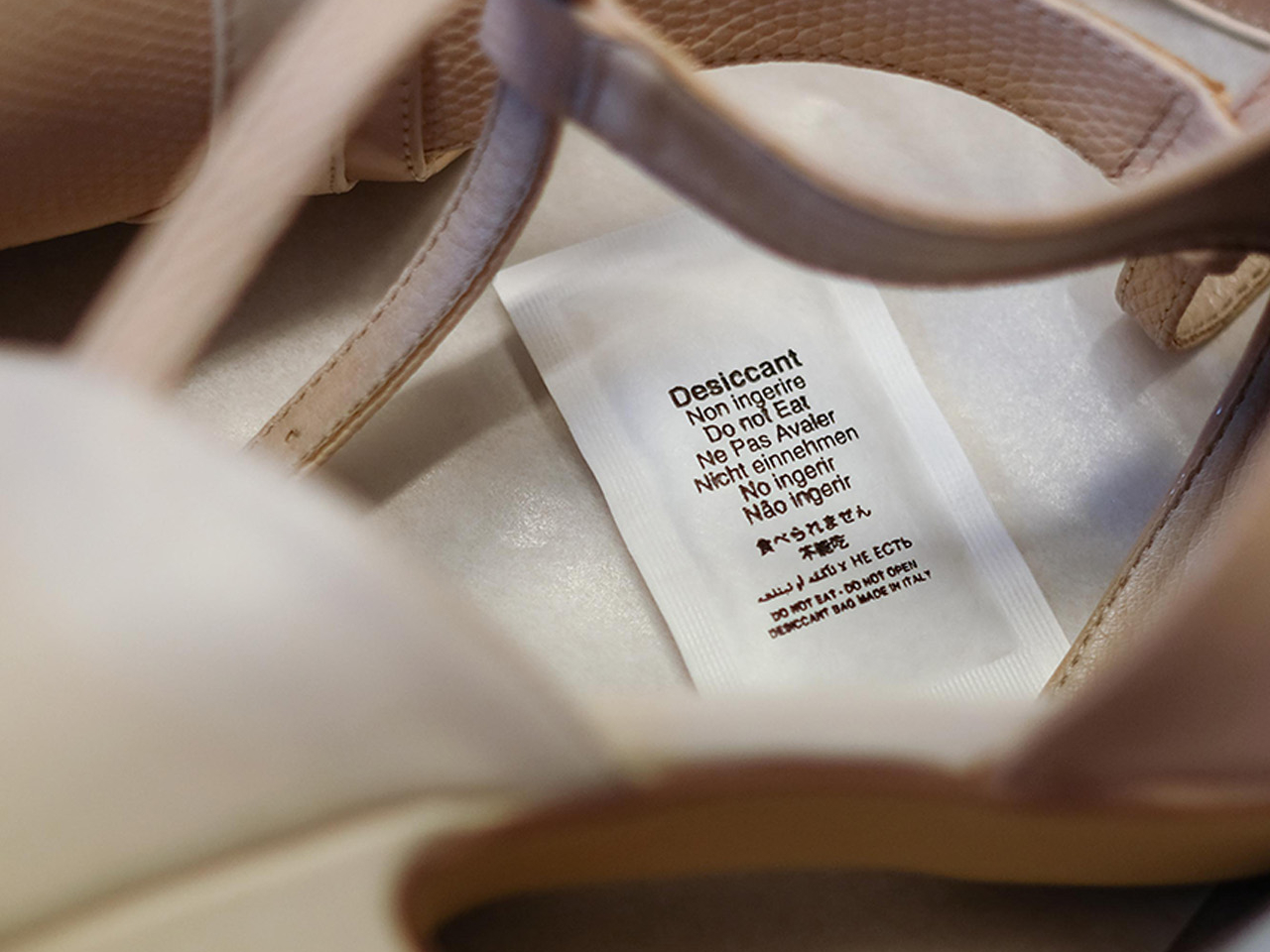

The Moisture Grabber is a dehydrating bag specifically designed for the leather goods market to eliminate quality issues associated with excess moisture in packaging. Preventing mold growth ensures that product quality remains intact even during long-term storage or sea transport in containers. The Moisture Grabber is manufactured in Italy, contains no fungicides, and does not emit any chemical substances.

Disidratante Naturale

Natural Activated Clay The dehydrating clay is a calcium bentonite that naturally adsorbs and traps moisture, removing it from the environment in which it is placed. The clay used in the Moisture Grabber complies with technical standards DIN 55473, MIL 3464E, NFH00320.

The dehydrating clay is identified by CAS number 1302-78-29. The dehydrating clay in the Moisture Grabber is a natural mineral quarry product, thus exempt from REACH registration obligations under Article 2, paragraph 7, letter (b). Besides being exempt from registration, the clay is a non-hazardous substance, free of SVHC substances, or any with PBT or vPvB classification, so there’s no need for exposure assessments or use communications along the supply chain.

Printing is done with inks suitable for food packaging, using typographic technology to ensure maximum readability, making the Moisture Grabber suitable for high-end products. The information on the bag is printed in Italian, English, Japanese, French, German, and Spanish.

The packaging allows a view of the natural desiccant inside the bag without releasing dust from the desiccant. The selected non-woven fabric is food-safe and classified as Type B (low dust release) according to DIN 55473 technical standards.

The number of dehydrating bags to use should be determined based on the product to be protected, the volume and type of chosen packaging, and the desired shelf life. Pay particular attention to the water vapor permeability of the packaging to be used.