Calculate how many desiccants to use in your packaging according to DIN 55474

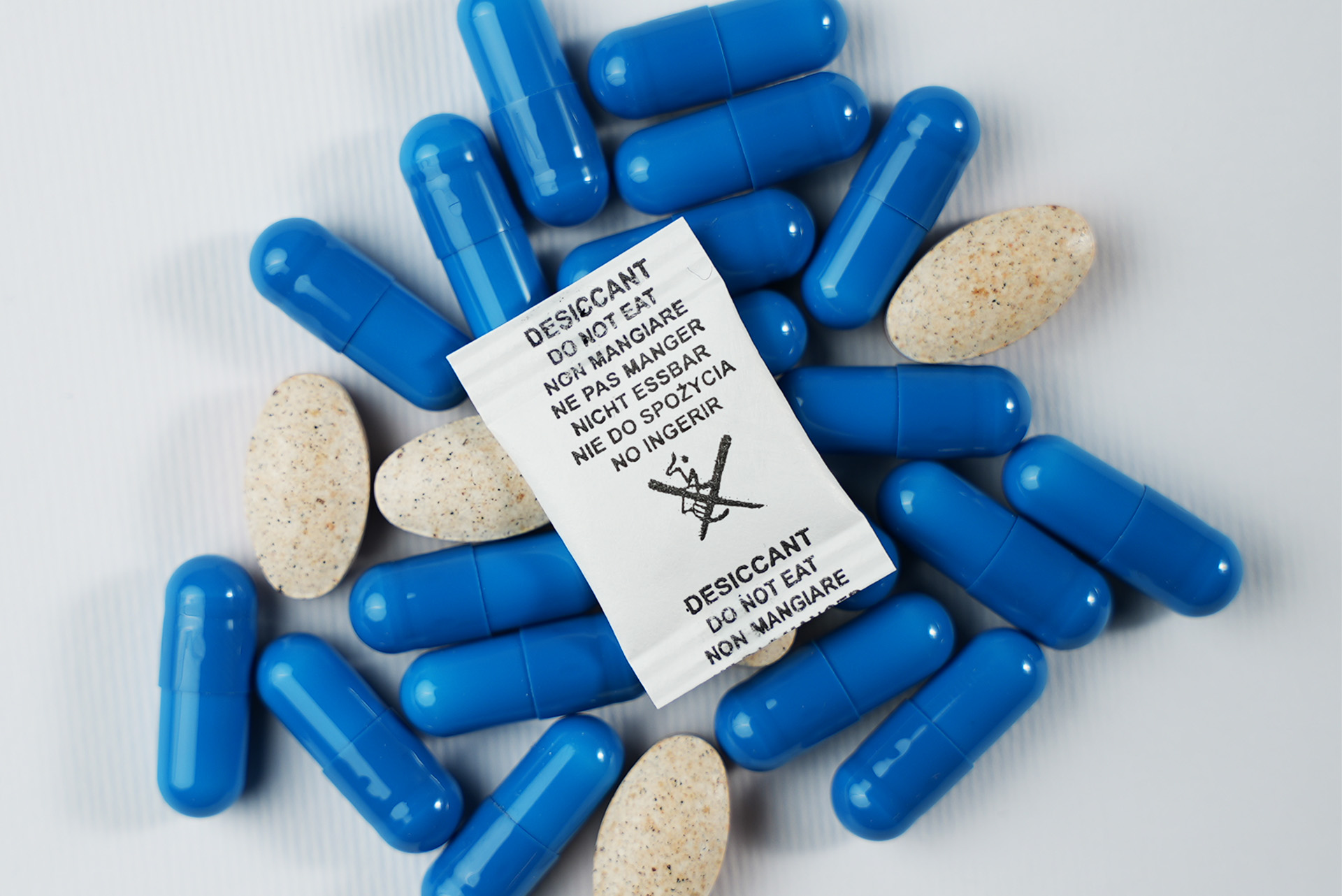

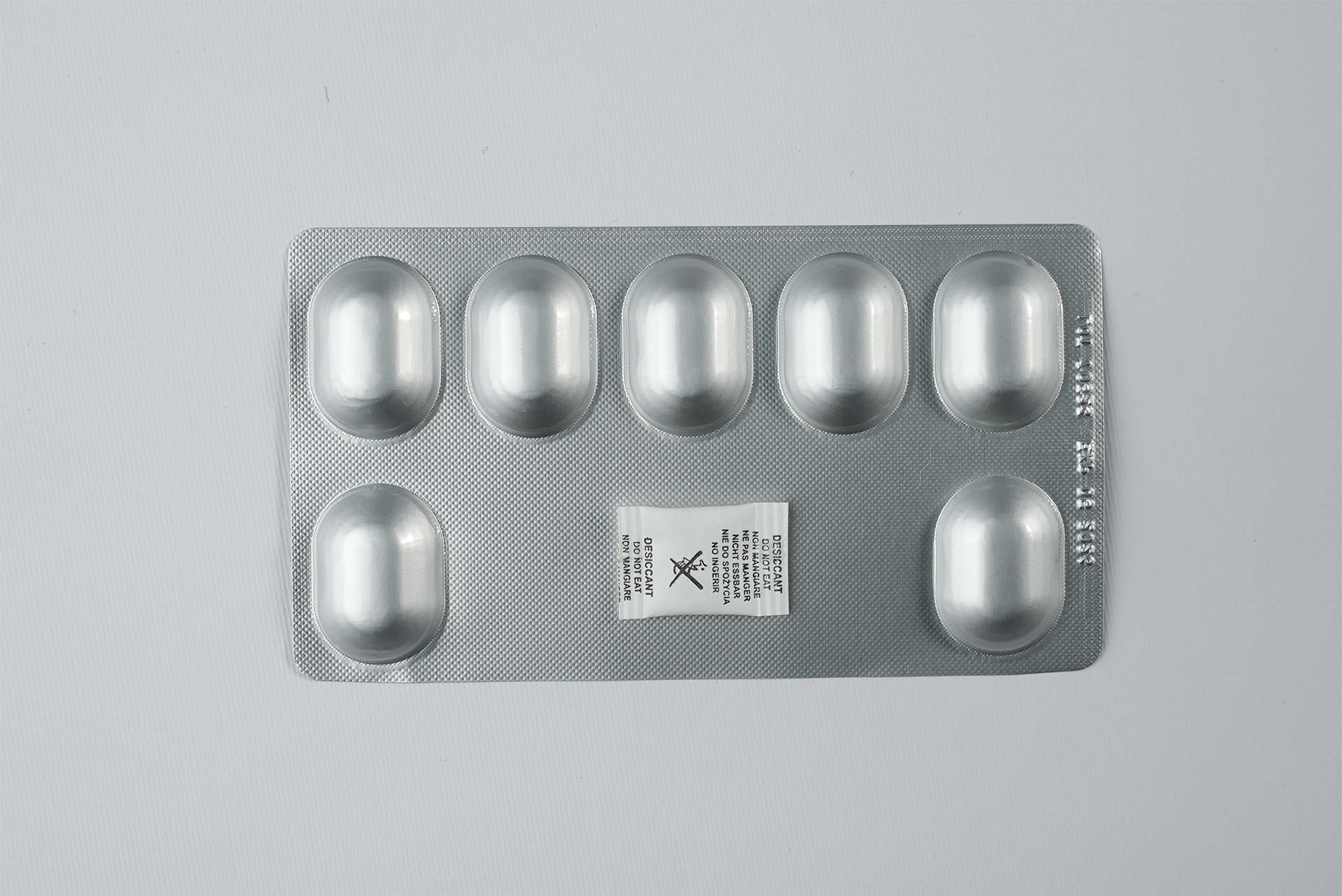

Desiccant bags are used to prevent moisture damage to materials during storage and transport

By absorbing moisture desiccant bags eliminate the problems it can cause within packaging. Desiccant bags do not release any gases and work by capturing moisture from the environment and from the materials they protect; this makes desiccant bags extremely easy and safe to use.

Levosil produces desiccant bags using the most common and effective raw materials known:

- Natural Activated Clay

- Silica gel

- Molecular sieves

In some specific applications, mixes of different desiccant materials are used, and Levosil can also offer this feature. Another key component of the desiccant bag is its envelope. Desiccant bag’s envelope regulates the passage of moisture (and therefore the absorption speed) into the desiccant bag and by retaining the dust within the desiccant bag, protects the packaging from potential contamination.

Levosil desiccant bags are available with various envelope options that can be chosen according to the desired result and the application in which the desiccant bags will be used. The most common packaging options are non-woven fabric, Type A or B according to DIN standards, and Tyvek.

Levosil has also introduced a line of completely compostable desiccant bags made with a 100% cellulose and bioplastic enclosure. This new enclosure eliminates the presence of plastic in desiccant bags, resulting in a product that is compostable at the end of its life. As a further effort to respect the environment and provide its customers with eco-friendly products, Levosil has also obtained FSC Chain of Custody certification on this special envelope wich is made also of paper.

Levosil offers desiccant bags that meet the most common industry specifications:

- DIN / AFNOR: Levosil’s desiccant bags comply with German DIN 55473, as well as French specification NF H 00321.

- JEDEC: Levosil Desiccant HICs and Desiccant bags meets the requirements for the dry packaging applications for semiconductors.

- Food & drugs: Levosil offers desiccant bags that meet relevant U.S. and European specifications for use in food and drug applications.